Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

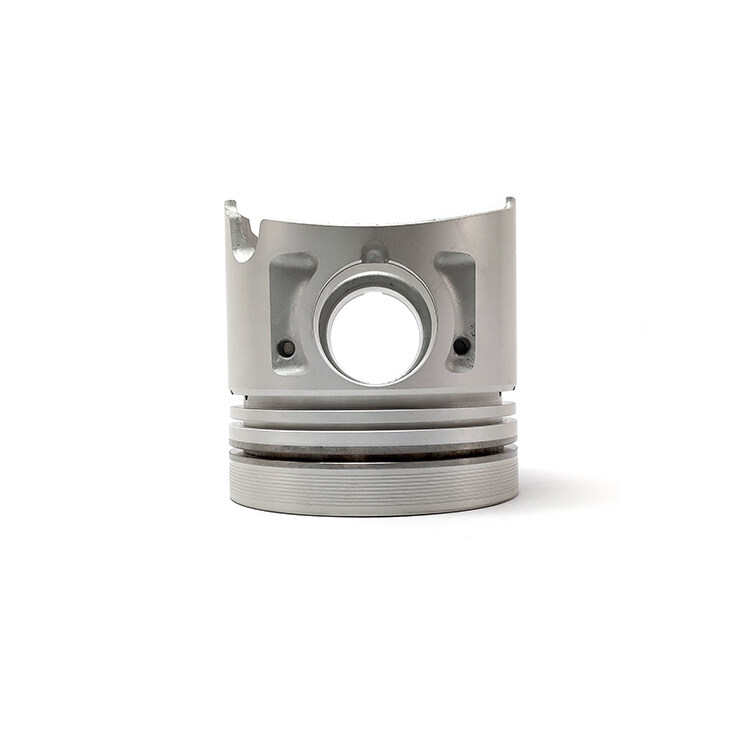

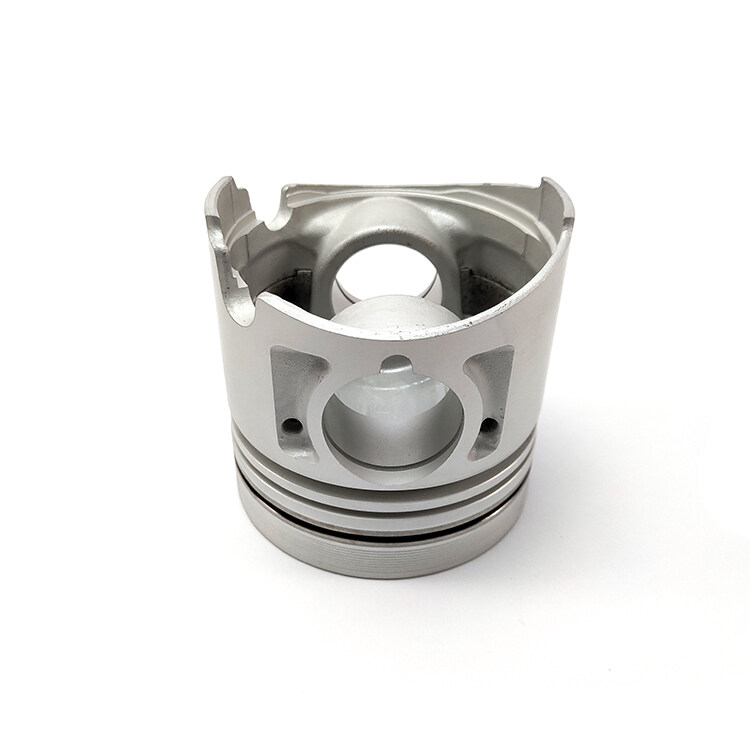

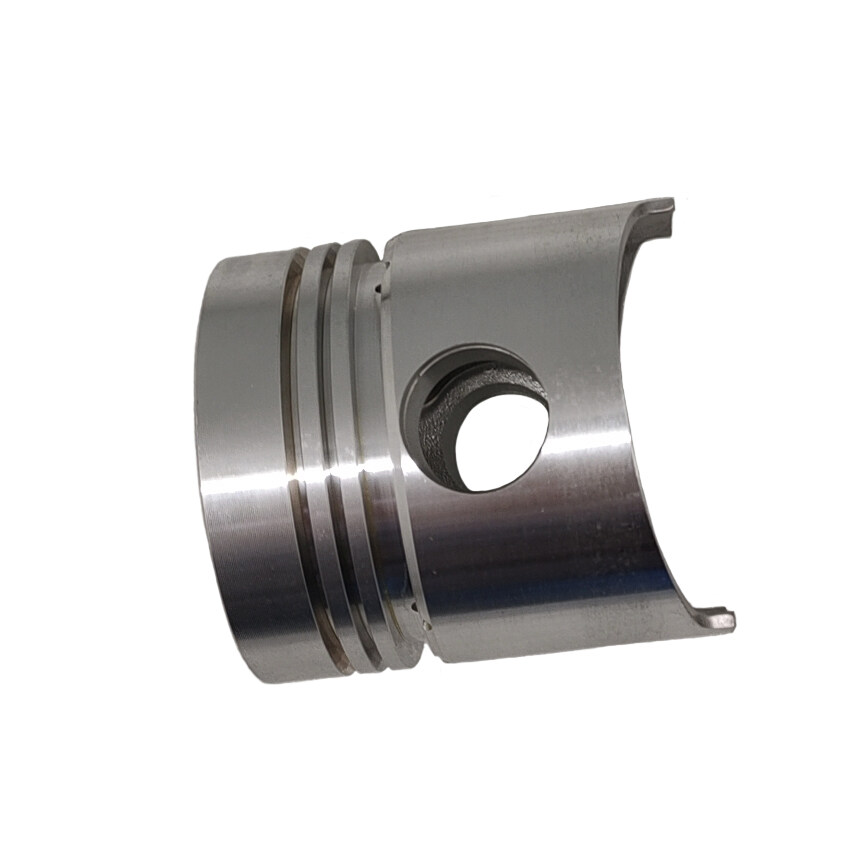

4JB1 Diesel Engine Piston 93mm 8-97108-621-0

The 4JB1 Diesel Engine Piston is a crucial component in the 4JB1 engine, renowned for its durability and performance in a wide range of applications. This piston plays a vital role in the internal combustion process, facilitating efficient power generation and fuel efficiency.

Crafted from high-strength materials, such as aluminum alloy or cast iron, the 4JB1 Diesel Engine Piston is designed to withstand the extreme heat and pressure conditions within the engine's cylinders. It features key elements:

-

Ring Grooves: The piston includes grooves for piston rings, which serve to maintain proper compression by sealing the gap between the piston and the cylinder walls. This prevents the escape of combustion gases and ensures efficient power generation.

-

Crown: The piston crown, situated at the top, is engineered to endure the high-temperature environment of the combustion process, offering heat resistance and structural integrity.

-

Skirt: The piston's skirt, located at the lower portion, helps guide the piston within the cylinder and provides stability, contributing to smooth engine operation.

-

Wrist Pin: The wrist pin, also known as the piston pin, links the piston to the connecting rod, enabling the piston's pivotal motion and the transfer of linear motion to the crankshaft.

The 4JB1 Diesel Engine Piston is designed to balance weight effectively and reduce vibrations, ensuring the engine operates smoothly. Furthermore, it may incorporate features like cooling channels or oil jets to manage temperature and prevent overheating.

The diesel engine piston is designed to withstand the high pressures and temperatures of diesel combustion, and is typically made of stronger steel. To prevent overheating, the piston features cooling channels or venting holes. Additionally, diesel engines use fuel injection to deliver fuel directly into the combustion chamber, which requires a specialized piston design that can accommodate the fuel injector.

Resistant to Tear and Wear:

The engine piston is primarily made of steel, which is a strong and durable material that can withstand the high pressures and temperatures of the combustion process. Steel pistons are resistant to wear and tear, and they can also be coated with materials such as ceramic or graphite to further enhance their durability, if you want to add coating, you can contact with us, then tell us your detailed information, then we will do as your following, because at this part, you can choose customized service. Additionally, the piston features cooling holes, to reduce friction and prevent overheating. Regular maintenance, such as oil changes and proper lubrication, can also help to prolong the life of the steel engine piston.

Bear in Terrible Environment:

The engine piston is designed to operate in a variety of environments, including those that are considered to be harsh or extreme. To ensure that the piston can withstand these conditions, it is typically made of strong and durable materials such as steel. These materials are resistant to wear and tear, and they can withstand the high pressures and temperatures of the combustion process.

Help Diesel Engine with High Compression Ratio:

Diesel engines are designed to operate with a higher compression ratio than gasoline engines, which means that the fuel-air mixture is compressed to a greater extent before ignition. This results in a more efficient combustion process, but it also places greater stress on the engine components, including the piston. The piston is also able to accommodate the fuel injector, which delivers fuel directly into the combustion chamber.

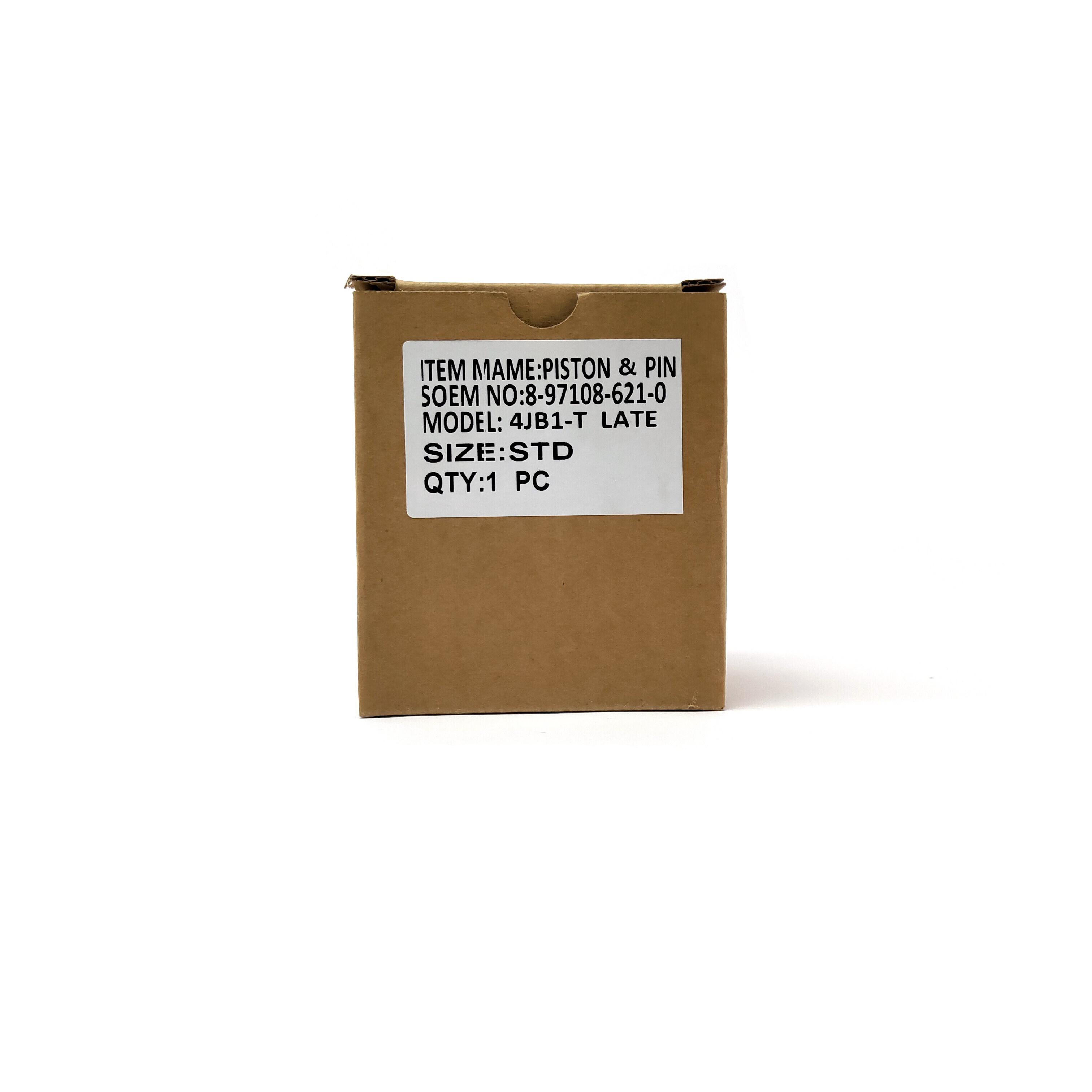

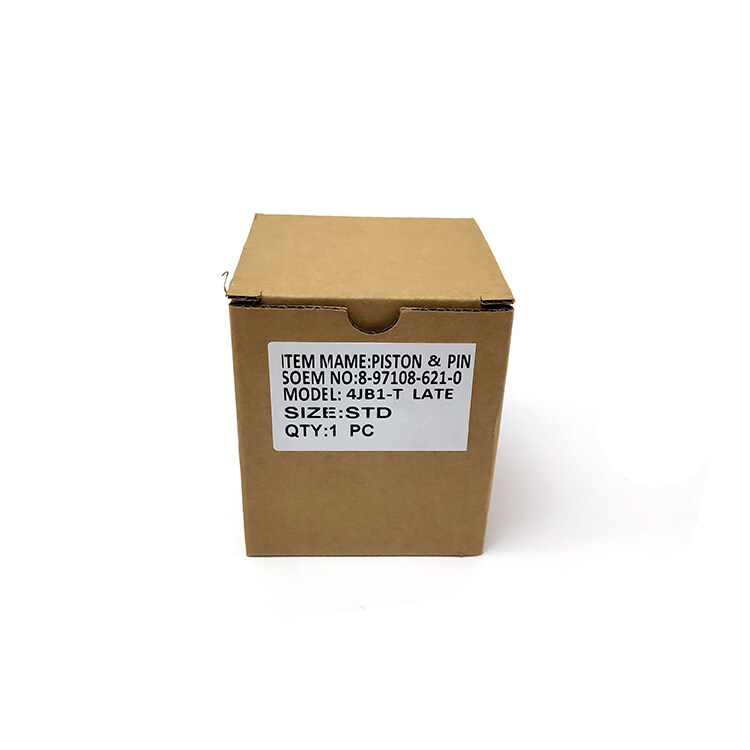

4JB1 Diesel Engine Piston Product Parameter:

|

Product Name |

Engine Piston |

|

Application |

Diesel Engine Parts |

|

Engine Number |

4JB1 |

|

Size |

STD |

|

OEM Number |

8-97108-621-0 |

|

Condition |

100% Brand-new |

|

No. of Cyl. |

4 |

|

Warranty |

6 Months |

|

Bore Diameter |

93.0mm |

|

Year |

1996-2009 |

|

Size |

93.0mm |

|

Piston TL |

91.8mm 4JB1T Engine Piston |

|

Combustion Chamber |

44mm |

|

Comp. Height |

51.9mm |

|

Pin Size |

34*78mm |

|

Piston Ring Size |

2.0+2.0+4.0mm |

|

MT |

19.3mm |

|

Surface Treatment |

Customized |

|

Payment Way |

T/T, L/C, Paypal, Western Union, UPS |

|

Car Model |

ISUZU |

What is an engine piston?

The piston is a reciprocating mechanism in the cylinder block of an automobile engine. The basic structure of a piston can be divided into top, head, and skirt. The top of the piston is the main part of the combustion chamber, and its shape is related to the form of the combustion chamber selected. Gasoline engines mostly use flat-top pistons, which have the advantage of a small heat absorption area. Diesel engine piston top often has a variety of pits, its specific shape, location, and size must be compatible with the requirements of the diesel engine mixture formation and combustion.

The engine is like the "heart" of the car, and the piston can be understood as the "center" of the engine, in addition to being in a harsh working environment, it is also the busiest one in the engine, constantly carrying out from the lower to the upper stop, from the upper to the lower stop point of reciprocal motion, suction, compression, work, exhaust ...... The interior of the piston is hollowed out, more like a hat, with round holes at both ends connecting the piston pin, which connects to the small end of the connecting rod, and the large end of the connecting rod connects to the crankshaft, transforming the reciprocating motion of the piston into the circular motion of the crankshaft.

There are three wrinkles at the skirt of each piston to install two gas rings and one oil ring, and the gas ring is on top. During assembly, the openings of the two air rings need to be staggered to act as a seal. The role of the oil ring is mainly to scrape off the excess lubricant splashed on the cylinder wall and to scrape the lubricant cloth evenly. At present, the widely used piston ring materials are mainly high-quality gray cast iron, ductile iron, alloy cast iron, etc.

In addition, the piston ring due to the different location, uses different surface treatment, including the first piston ring's outer circle surface is usually chrome-plated or molybdenum spray treatment, mainly to improve lubrication and improve the wear resistance of the piston ring. Most of the other piston rings will be tinned or phosphate, mainly to improve wear resistance.

Piston top carbon accumulation

If the piston ring is not properly installed or poorly sealed, it will cause the oil on the cylinder wall to run up to the combustion chamber and burn with the mixture, causing the oil burning phenomenon. If the piston ring and cylinder wall clearance are too small or the piston ring is stuck in the ring groove because of carbon, the piston to do up and down the reciprocating motion, it is likely that the cylinder wall will be scratched, after a long time will form a deep groove on the cylinder wall, which is often called "pull cylinder" phenomenon. The cylinder wall has a groove, and poor sealing, which will also cause an oil-burning situation. Therefore, you should regularly check the working condition of the piston to avoid the above two situations and to ensure that the engine is running well.

The role of the engine piston

The role of the engine piston is to bear the pressure of the combustion gas, through the gas pressure by the piston pin to the connecting rod, push the crankshaft rotation output power. The piston is driven by the connecting rod to complete the intake, compression, exhaust three auxiliary stroke work.

The piston is mainly composed of the top, head, and skirt. Piston top and cylinder head, cylinder wall together to form a combustion chamber. The role of the piston skirt is for the piston in the cylinder to do reciprocating motion guide and bear side pressure.